Bandelementen zijn cirkelvormige verwarmingselementen die zijn opgebouwd uit hoogwaardig weerstandsdraad dat elektrisch geïsoleerd wordt door een mica of keramische isolatie. Ze worden gebruikt voor diverse toepassingen, onder meer in de machinebouw, plasticindustrie en rubber verwerkende industrie.

Technisch advies?Bandelementen hebben zeer veel industriële toepassingen, maar worden vooral veel toegepast in de machinebouw voor het opwarmen van korte stukken leidingwerk en in de kunststof- en rubber verwerkende industrie. Voorbeelden zijn bijvoorbeeld extrusie- en spuitmachines. Ook als vatverwarming zijn bandelementen toepasbaar.

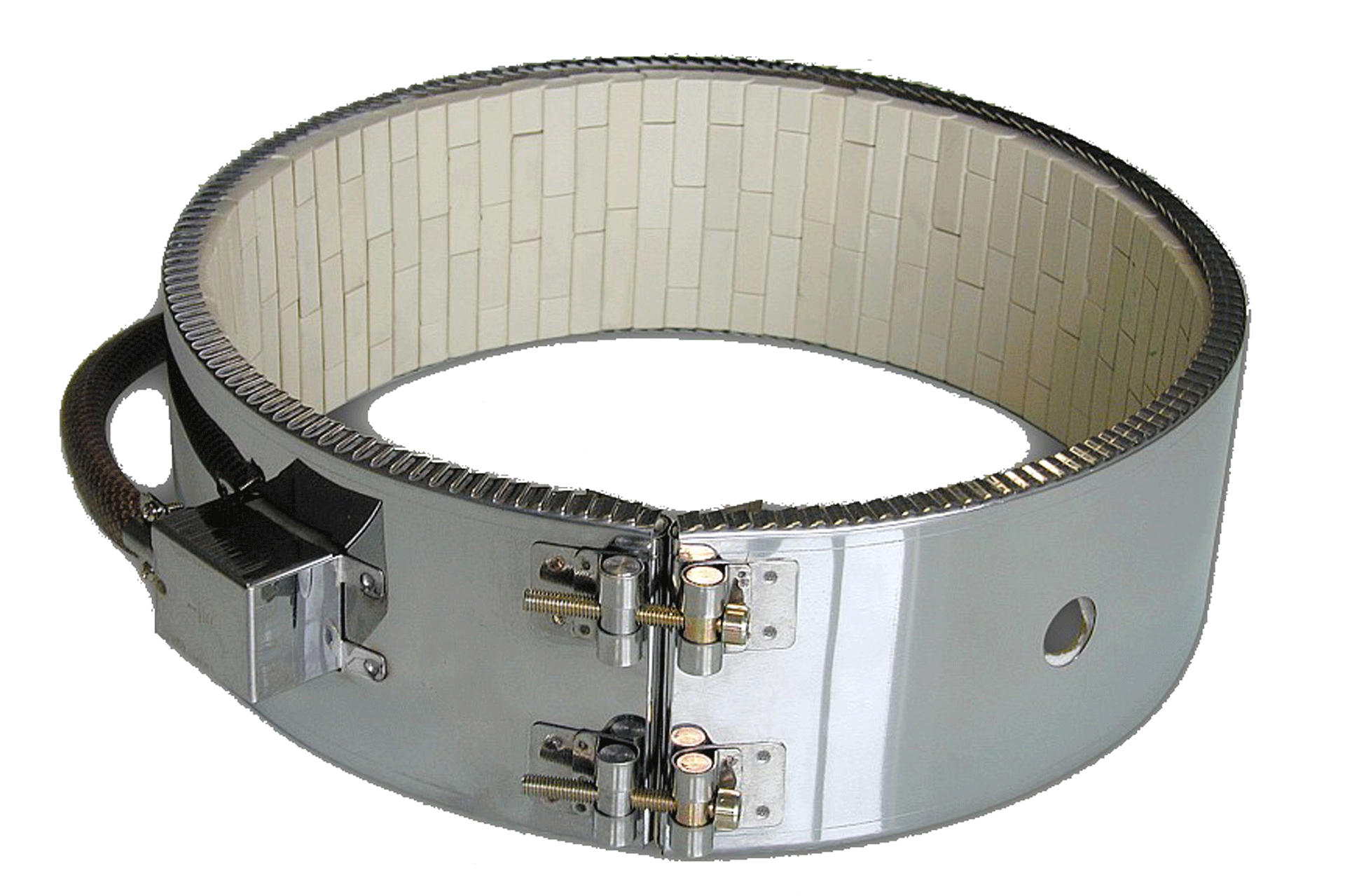

Bandelementen zijn onder te verdelen op basis van het isolatiemateriaal, namelijk mica of keramiek. De keuze hiervan is afhankelijk van het benodigde vermogen en werktemperatuur. Een element kan uit meerdere segmenten bestaan die met elkaar verbonden zijn door klemmen of scharnieren.

Bandelementen zijn cirkelvormige verwarmingselementen die zijn opgebouwd uit hoogwaardig weerstandsdraad dat elektrisch geïsoleerd wordt door een mica of keramische isolatie. Deze zijn meestal gevat in een metalen mantel. De mantels kunnen bestaan uit verzinkt of gealuminiseerd plaatstaal, messing of roestvast staal.

Elementen met een diameter boven de 500mm dienen altijd uit twee of meerdere segmenten te bestaan. Voor de elektrische aansluiting bestaan een groot aantal opties. Om bijvoorbeeld thermokoppels te plaatsen dan wel uitstekende delen te omvatten kunnen de elementen voorzien worden van gaten of uitsparingen.

De neuselementen zijn net als de mica elementen opgebouwd uit een weerstandsdraad die elektrisch geïsoleerd wordt door mica isolatie. De mantel bestaat echter niet uit twee losse platen maar uit een platgewalste messing. Door dit walsen wordt een zeer glad oppervlak en een goede verdichting van het element gecreëerd waardoor zeer goede warmtegeleiding ontstaat.

| Maximale temperatuur | ca. 340 graden Celsius |

| Maximale watt belasting | 4,5W / cm2 |

| Diameter | 50 – 380 mm |

| Hoogte | 50 – 420 mm |

| Spanning | variabel |

| Maximale temperatuur | ca. 900 graden Celsius |

| Maximale watt belasting | 9W / cm2 |

| Diameter | 60 – 630 mm |

| Hoogte | 30 – 450 mm |

| Spanning | variabel |

| Maximale temperatuur | ca. 450 graden Celsius |

| Maximale watt belasting | 6,5W / cm2 |

| Diameter | 25 – 100 mm |

| Hoogte | 20 – 80 mm |

| Spanning | variabel |

| Isolatie | mica |

| Aansluitrichtingen | axial / radial / tangential |

Bij Heating Group is uw verwarmingsvraagstuk in goede handen. Onze specialisten adviseren u graag over de verwarmingsoplossing die het beste past bij uw situatie of project.

Zo bent u verzekerd van een betrouwbare oplossing.

Onze specialisten adviseren je graag. We zorgen dat je altijd de beste oplossing krijgt voor je verwarmingsvraagstuk.

We werken alleen met hoogwaardige materialen en vakkundige mensen.

Bij ons krijg je direct een specialist aan de telefoon. Geen keuzemenu of receptioniste maar direct vakkundig advies.

Heating Group International B.V. © 2024

Heb je een vraag of advies nodig? Op onze klantenservicepagina vind je veelgestelde vragen en op de contactpagina staat alle informatie die je nodig hebt om contact met ons op te nemen.